1.Basic concepts of tungsten carbides

Tungsten carbide, also known as tungsten carbide material, is a composite material composed of metals, intermetallic compounds, and non-metallic powders (such as tungsten carbide, titanium carbide, etc.). Compared with traditional metal materials, tungsten carbides have higher hardness, strength, wear resistance, and corrosion resistance, as well as good mechanical properties and service life.

2.The basic composition of tungsten carbides

Tungsten carbides are typically composed of the following elements and substances:

1. Carbides: tungsten carbides usually contain carbides, such as tungsten carbide (WC), titanium carbide (TiC), etc. The hardness of carbides is extremely high, which can improve the wear resistance and cutting performance of tungsten carbides.

2. Metal powder: tungsten carbides also contain some metal powders, such as cobalt powder, nickel powder, etc. These metal powders can make tungsten carbides more tough and corrosion-resistant.

3. Non metallic powders: tungsten carbides also contain some non-metallic powders, such as oxides, nitrides, etc. These non-metallic powders can enhance the hardness and wear resistance of tungsten carbides.

3.Characteristics of tungsten carbides

Tungsten carbide materials have the following characteristics:

1. High hardness: The hardness of tungsten carbides is higher than that of most metal materials, and can reach HRA80 or above.

2. High strength: tungsten carbides also have relatively high strength and can withstand large external forces.

3. Good wear resistance: tungsten carbides have excellent wear resistance and can be used in extreme environments.

4. Corrosion resistance: tungsten carbides have good resistance to most chemical corrosion.

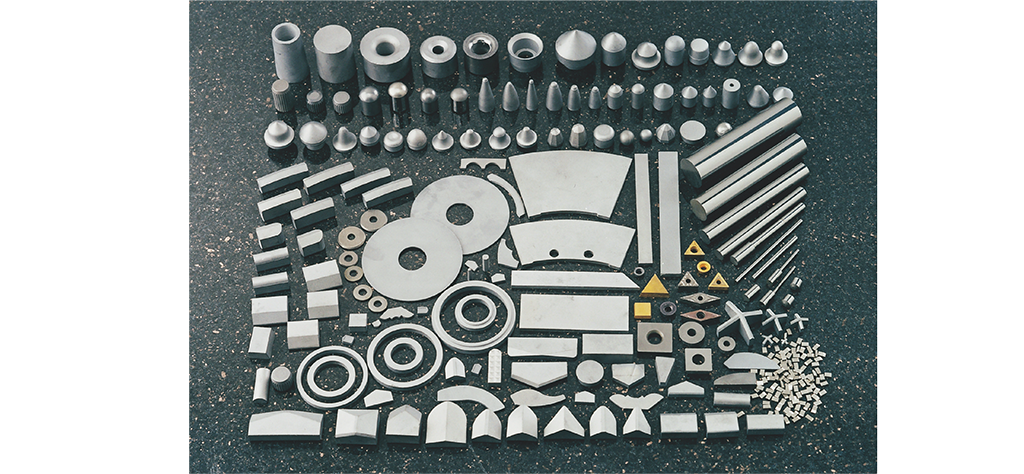

4.Application fields of tungsten carbides

Tungsten carbide materials have a wide range of applications, such as:

1. Metal cutting: tungsten carbides are used to manufacture cutting tools, drills, milling cutters, etc., which can improve cutting accuracy and speed.

2. Mining tools: tungsten carbide can be used to manufacture mining tools such as drill bits, mining drills, and inserts.

3. Mechanical components: tungsten carbide can be used to manufacture mechanical components such as bearings, gears, and ear wheels.

4. Welding: tungsten carbides can be used to manufacture materials such as welding rods and wires.

5.The difference between tungsten carbides and other metal materials

Compared with other metal materials, tungsten carbide materials have higher hardness and wear resistance, but relatively poor toughness and plasticity. In addition, the processing difficulty of tungsten carbides is relatively high, requiring specialized processing techniques and equipment.

Conclusion

Tungsten carbide materials play a very important role in modern industrial production, with their high strength, high hardness, and excellent wear resistance, making them widely used in the manufacturing industry. In future industrial production, we believe that the application range of tungsten carbides will be more extensive, bringing more convenience and development opportunities to the manufacturing industry.